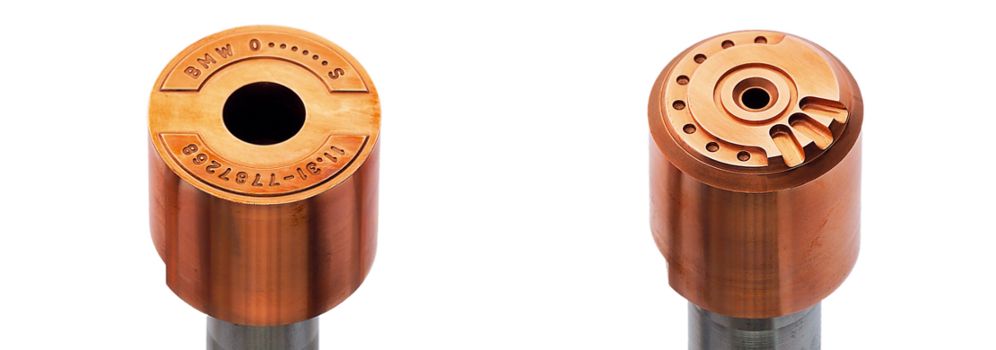

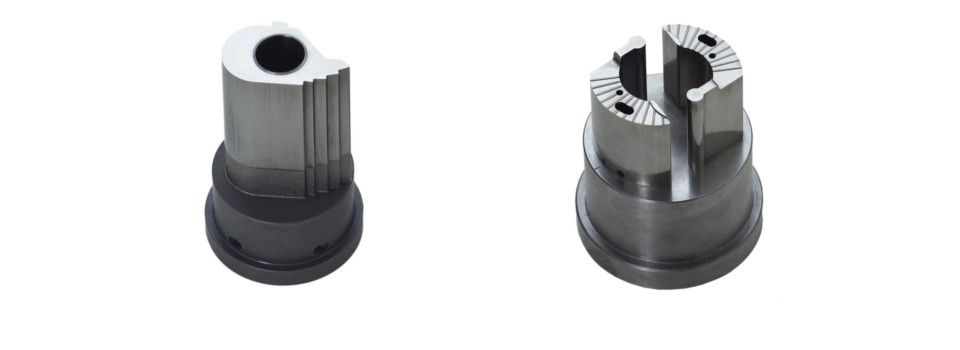

SINTERING TOOLING

We supply components for the automotive sector, internal processes are complemented by subsequent finishings, degreasing, carbonitriding, zinc-nickel, tempered, nut and bolt insert, welding.

Our production facilities allow us to build the most complex elements in the tooling sintering industry, in terms of the shapes and finish roughness concerned. We build dies and punches in Asp-Vanadis and Carbide steels.

This section is climate controlled, which allows us to control our finishes with a guarantee of accuracy, by maintaining constant thermal stabilisation on the precision machines. All finishes are made directly on the materials with treatments between 60-64 Hrc, either via high speed machining, wire EDM, penetration EDM or with finishing roughness up to Ra 0.1 micra.